Production of prototypes and wide range of products for short production lots without the need to invest in expensive tools. Our production processes are designed and accomplished on CAD/CAM. The modern punching presses and press brakes are able to deal with any type of material.

Materials

We punch and bend from: carbon steel, nickel, stainless steel, aluminum, plastics, brass, copper, bronze.

Design office

Our production processes are designed and accomplished on CAD/CAM.

High standards

We prepare APQ, documentation for PPAP approval, complete IMDS.

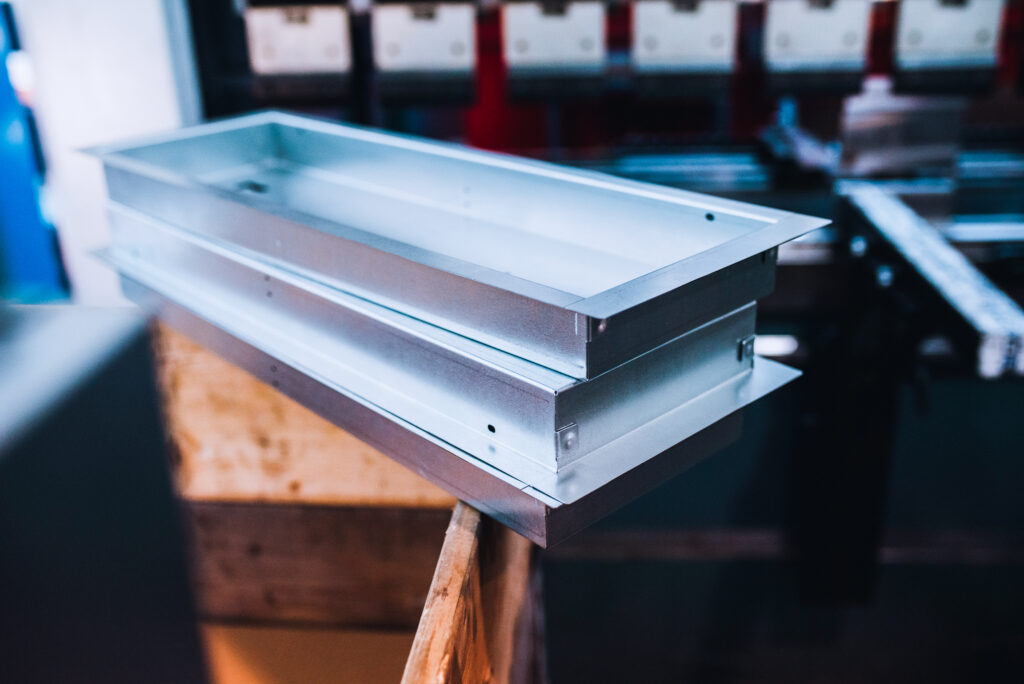

CNC punching & bending

We can work with any type of material and produce metal comopnents in high volumens, as well prototypes and short production lots without investing in expensive tools.

from 0,5 to 6 mm

Thickness of manufactured components

1250 x 2500 mm

The scope of machining axes X,Y

5000 mm

The range of machining X, Y, Y, one reposition

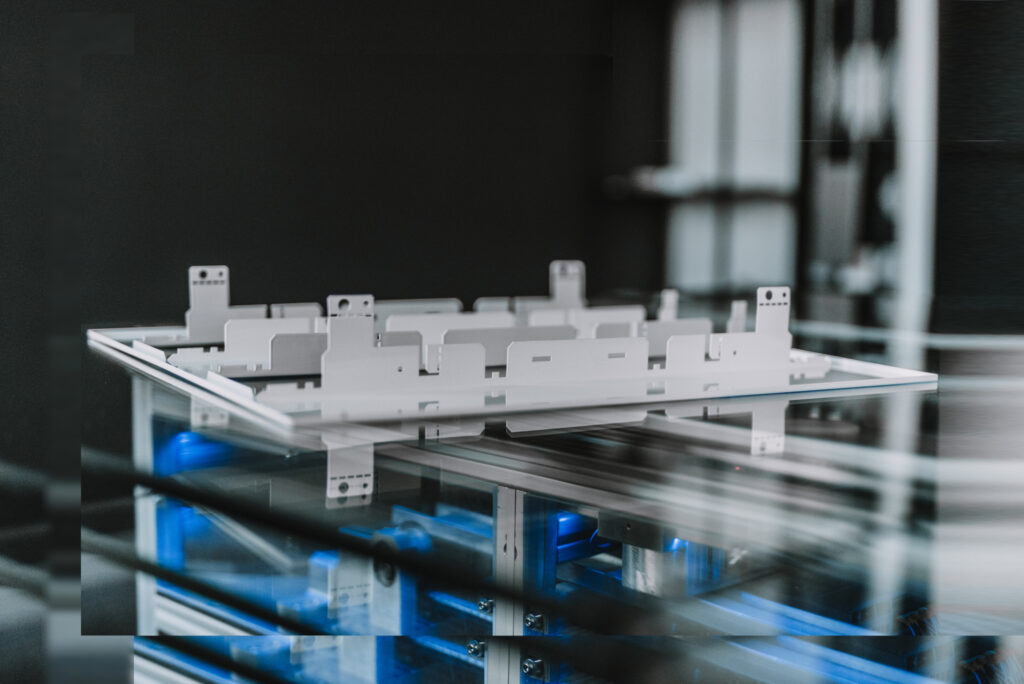

Quality, efficiency - automatic bending

Bending station equipped with a modern Fanuc brand robot, which provides:

- Motion repeatability with an accuracy of ± 0.03 mm;

- Lifting capacity : 35 kg

- Precise stabilization during individual bends on the part;

- Project implementation time in terms of programming and robot preparation: 2 - 4 weeks.

Our machine park:

- high-speed presses of high-production (with a productivity of up 400 strokes per minute), eccentric, crank and double-crank, hydraulic, CNC punching & bending which are characterized by pressure from 2.5 to 500 tonnes

- 18 lines for stamping and punching (which allow to install the tools on the table of maximum size 3100 x 2100 mm)

- CNC press brake of bending length up to 3000 mm

- CNC punching press with the surface area of punching of 1000 x 2500 mm (but in the reposition up to 5000 mm)

- robotic bending station

- laser

- milling plotters

- saws for cutting aluminum section

- assembling and testing devices